Pellets are a great fuel but the delivery, storage and conveying the fuel out of storage needs to take account of their limitations.

When designing a pellet store you need to think about the practical delivery volume; pellet supply companies have to charge for the transport costs, so if you can only accept a 2 tonne delivery you will have to pay more per tonne than a 5 tonne delivery.

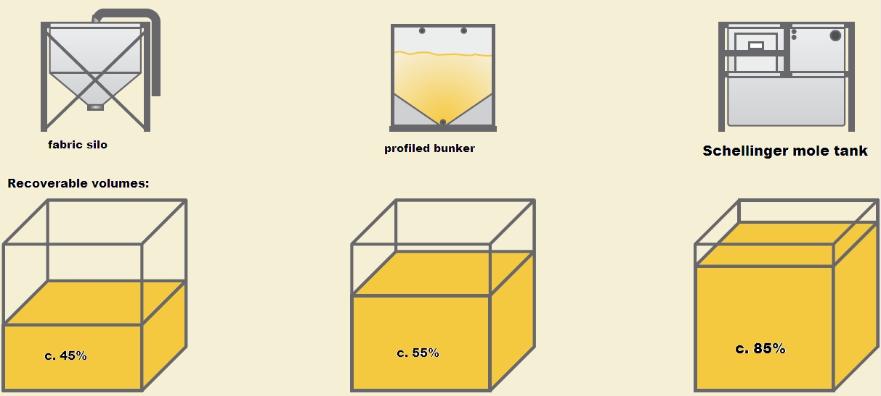

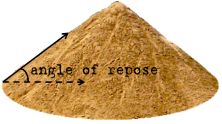

The "angle of repose" for pellets is commonly quoted as around 45 degrees so it follows that people design stores with 45 degree slopes to channel pellets to a pick up point. While certainly any less than this angle will result in pellets not flowing, experience has shown that, even at 45 degrees, pellets may not flow without intervention i.e. you need to poke them.

Whenever pellets are moved they will be 'damaged', the severity of damage varies but the overall result is the percentage of fines generally increases from production to final consumption. As pellets are emptied from conventional, sloped, stores a process of particle separation takes place - this can create several issues;

- the angle of repose increases

- pockets of fines accumulate within the store

The Mole takes the extraction point to the pellets rather than attempting to move the pellets to the extraction point through slopes or mechanical means. This means that less damage occurs and the level of fines fed to the boiler tends to remain the same from top to bottom of the store.