Pellet Mole E3 for large pellet storage

Based on the highly successful patented mole technique the Pellet Mole E3 continues development of the extraction technique "from above". The E3 is designed for larger pellet plants with boiler outputs from 40 to 300 kW and an annual pellet demand of several hundred tonnes. The typical storage sizes are up to 40 tons or 60 cubic meters capacity.

Equipped with the latest sensor technology, E3 recognizes the surrounding surfaces of his Pellet store and moves purposefully to the pellets. The star-shaped Round brushes made of high-loadable polyamide dose the pellet gently before the suction port and move the E3 smoothly over the pellet supply. Due to the unique way of working there is no need for time-consuming and costly installations. The work area is up to 6 m in diameter and allows for the hose suspension also needed for long, narrow storage rooms.

Terms of Reference

Pellet removal system for gentle removal of pellets from a pellet storage in combination with pellet boilers with pneumatic conveyor.

-

Suitable for all spatial geometries, for example, round, square, rectangular.

-

Allows the use of small spaces for pellet storage.

-

Equipped with contact switches, tilt sensor and three independently driven brush drives for intelligent motion control.

-

Prevention of segregation processes in the pellet storage. Smooth and gentle removal of the fuel from the top.

-

Low maintenance and easy to install. Mounted in a few steps, and for service, easily taken from the pellet store.

-

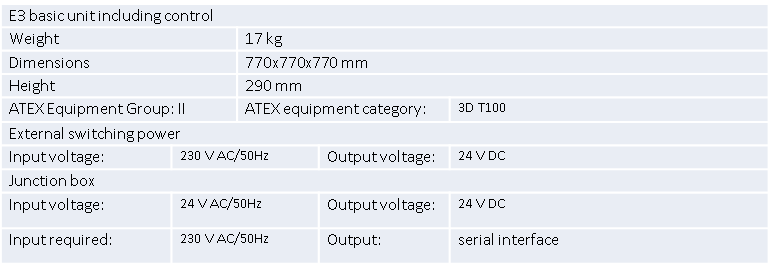

ATEX Group II; ATEX equipment category 3D T100 ° C.

-

Easy connection to the boiler vacuum (230 VAC/50Hz).

Complete system consisting of:

-

Pellet Mole E3, completely assembled with:

- Housing with centered intake manifold for hose with nominal diameter 50 mm

- Three mounted band-switches for wall detection

- Three drives, 24 V DC, 18 W with wear-resistant round brushes and bearings

- Control with integrated tilt detection

-

Connection with external switching power supply, input 24 VDC Output for component support and USB interface for data communication..

-

8 m special wire spiral hose, ready to install with 9 m electric cable and dustproof cable connector and three sprung cords for hose support.

-

Panel feed-through for suction and return hose DN 50, including all hardware and mounting material. Optional fire protection sleeves.

-

Mounting material and spare parts for the hose assembly

-

Manual or automatic lifting device (options)

Pellet Mole E3 for large pellet storage and accessories

Complete removal system according to the above description in two versions: E3 basic unit including control